Process | Equipment needed | |

1 | dough bulk dividing | dough divider |

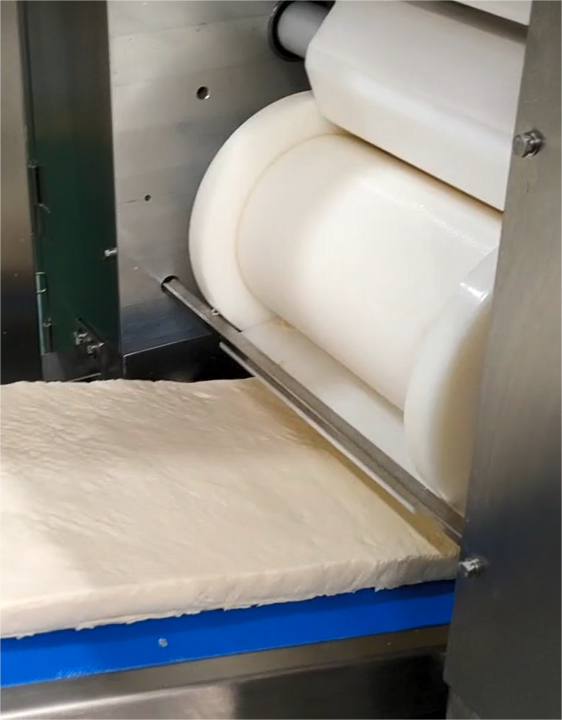

2 | dough preliminarily rolling | dough arranging machine |

3 | continuous thinning | planetary roller*4 |

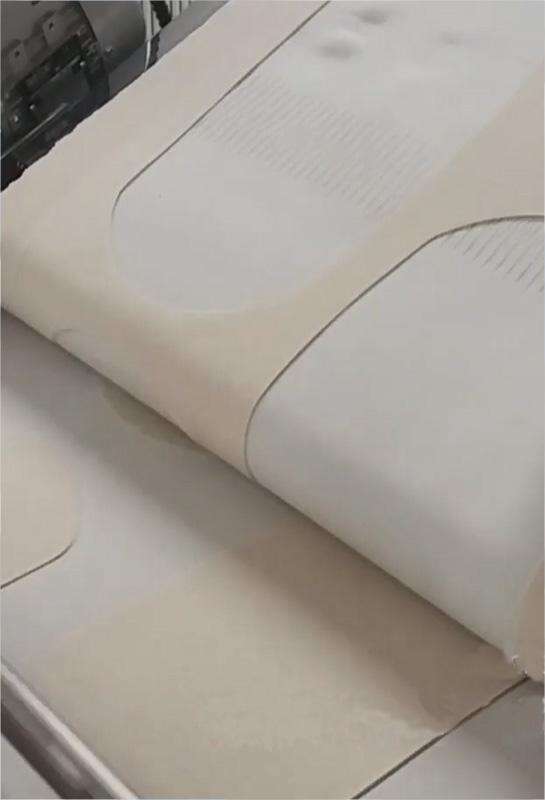

4 | dough ribbon stretching | dough stretcher |

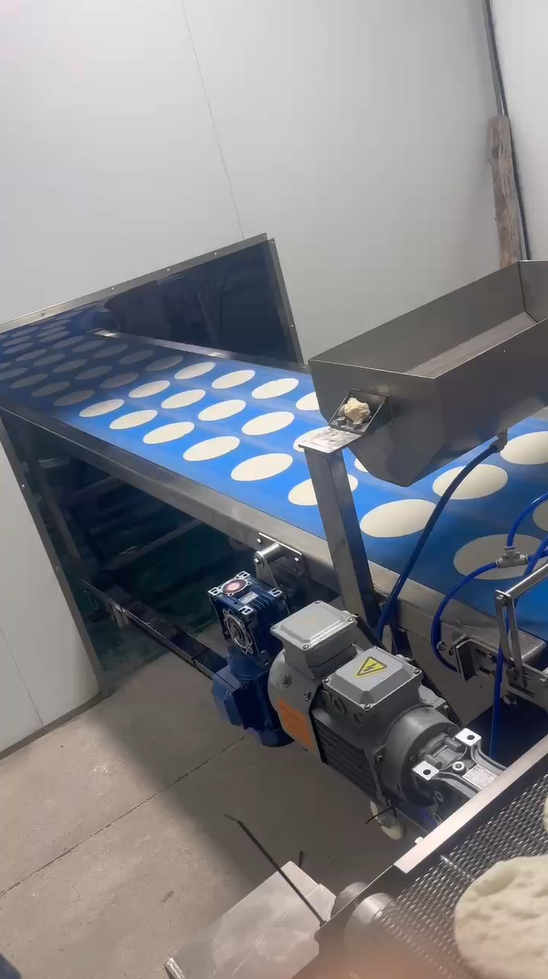

5 | moulding | moulder |

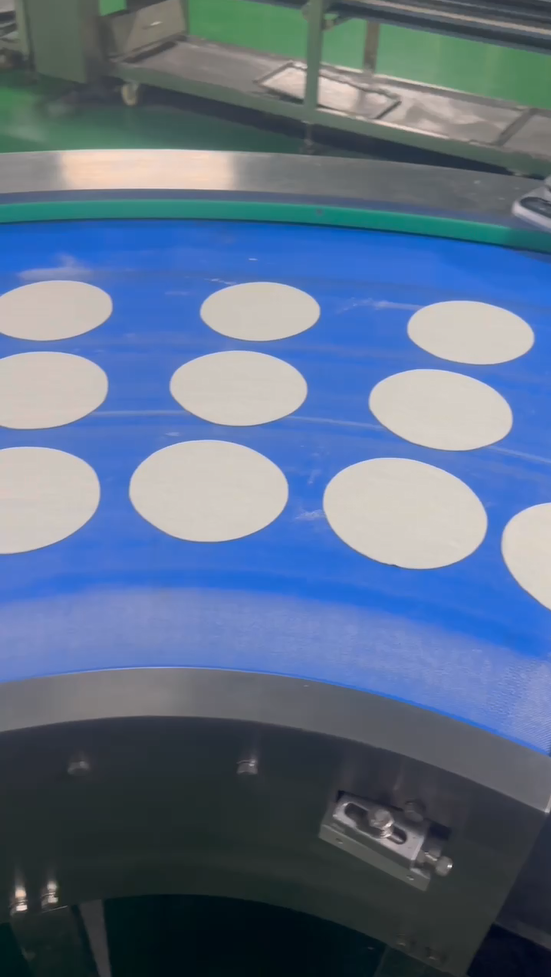

6 | conveying | conveyor |

7 | baking | oven |

8(optional) | water spraying | sprayer |

9 | cooling | cooler |

1) The dough is preliminarily rolled, and the dough surface becomes smooth and the thickness becomes uniform.

2) The continuous thinning/rolling mechanism further processes the dough.

3) The dough is made into dough ribbon, and the dough ribbon is stretched with a stretching machine.

4) Stretching and thinning until the thickness is less than 1mm.

5) Moulder cut the dough ribbon into desired shape and size.

6) Equip the right oven for baking.

7) Cooling for packing.

*We accept customization, please tell us your needs, such as output, bread size, etc., the more detailed the better. We will do our best to provide you with a satisfactory solution.

Juheng

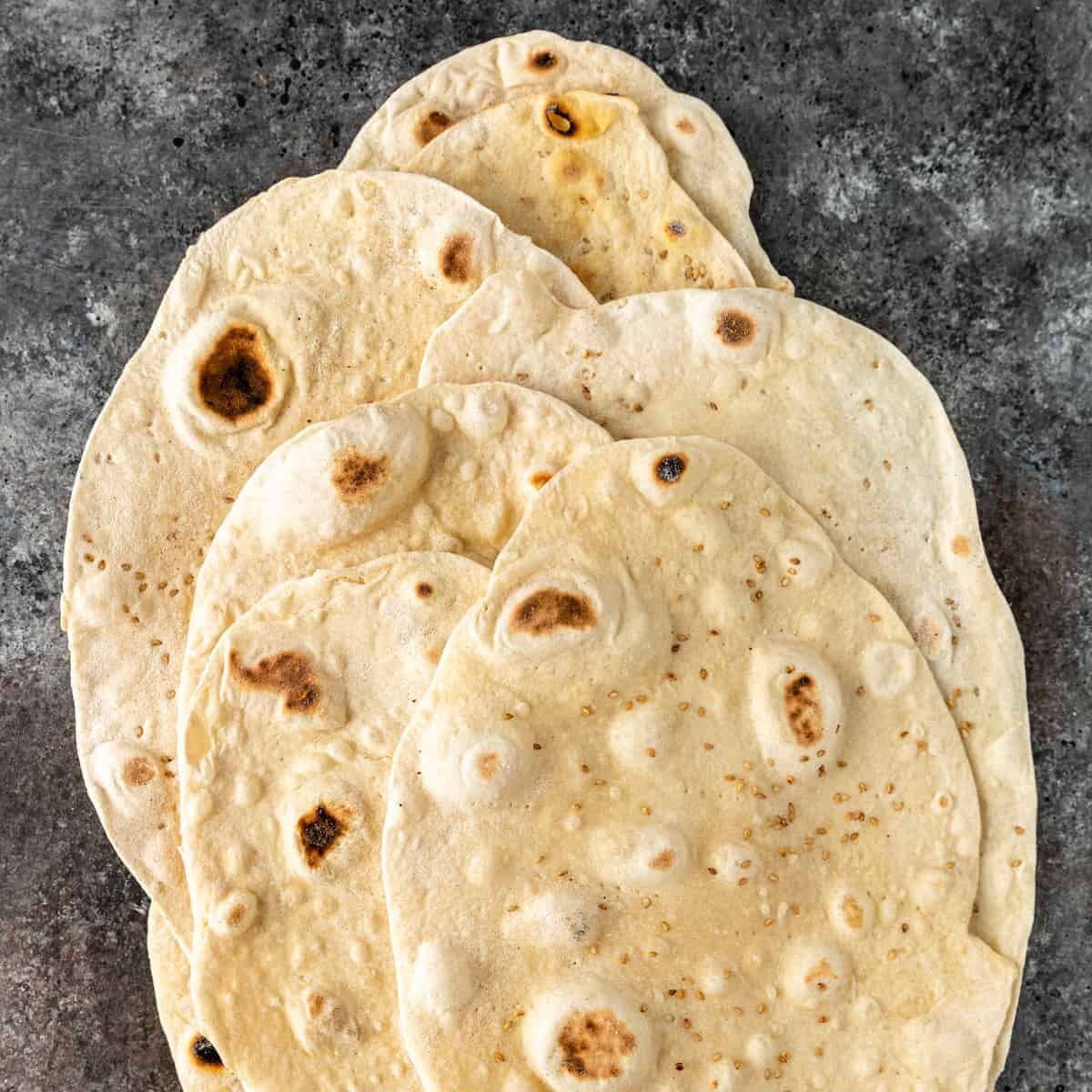

CE lavash is manufacturing that automatic customized lavash molding line food processing for commercial use could be the perfect solution commercial food businesses trying to develop their manufacturing abilities. This lavash is personalized was created to meet up with the needs of high-volume bread manufacturing, aided by the added benefit to be completely automated for optimal efficiency.

Built from durable, top-notch materials, the Juheng CE lavash is production automated customized lavash molding line food processing for commercial usage was created to final and withstand the rigors of constant usage. Featuring its advanced level CE certification, customers could possibly be fully guaranteed for this product quality and safety for this item, making this an investment is audio almost any meals operation is commercial.

The Juheng CE lavash automated line manufacturing lavash molding line food processing for commercial usage was created to streamline the bread making procedure from dough mixing a great deal in connection with real way right through to shaping, baking, and packaging. The machine can manage an amazing quantity of types and sizes, making this an instrument is food establishment that versatile. The molding is automated fast and consistent shaping of the dough, even though baking is exact perfectly prepared lavash bread each time.

The Juheng CE lavash production is automated customized lavash molding line food processing for commercial usage also boasts an easy-to control-use, enabling operators to improve settings and monitor progress with ease. This feature is particular specific the line a great choice busy commercial kitchens, where rate and effectiveness are very important. Operators can certainly and effectively adjust the equipment's settings to meet with different production, rendering it a really tool flexible any establishment attempting to expand their item offerings.

The Juheng CE lavash automated line is manufacturing lavash molding line food processing for commercial use are a facile task to keep and clean alongside its impressive production capabilities. Its simple design permits for quick use of critical components, making maintenance breeze is routine. The equipment's durable construction guarantees it might probably stay real to daily hold and tear without compromising on quality performance.

Our friendly team would love to hear from you!